+96650000000

Sales@saprexme.com

Port service and spare parts supplier

Hydrolic systems and spare parts supplier

Heavy equipment spare parts supplier

Navigation Aids Buoys

Marine offshore spare parts supplier

Port service and spare parts supplier

Heavy equipment spare parts supplier

Marine offshore spare parts supplier

Marine offshore spare parts supplier

Navigation Aids Buoys

We supply genuine, OEM, and remanufactured parts for main and auxiliary diesel engines, as well as related engine room equipment delivering top quality, reliability, and flexible service through our global network for most major 2-stroke and 4-stroke engine makers.

Over the years, our chemical product range has been increased and developed, and we have expanded our supply network around the world. Today, demonstrating our commitment to delivering exceptional quality and service to our global clientele

Our extensive range features navigational aids, mooring buoys, and meteorological buoys, all engineered to endure the harshest marine environments. Each buoy is meticulously crafted for superior durability and reliability, ensuring exceptional performance in every application.

We specializes in marine electrical cables and accessories, offering high-quality products at competitive prices. Our range covers all voltage levels and includes navigation lights, marine cables, lamps, batteries, switches, relays, motors, chargers, and more.

We supply all IMPA listed items and offer delivery to all ports with competitive prices and quick response time.

Our company sells all heavy equipment spare parts of world-renowned brands, such as Dozer, Dumper, Crane, Shovel, and power generators manufactured by OEM, such as Caterpillar, Komatsu, TCM , JCB and Cummins.

Safety , Health and Environmental

The company has grown to become a leading industrial equipment provider in Saudi Arabia, offering a comprehensive range industrial equipment lines and services to diverse sectors like oil & gas, petrochemical, and utilities.

During disassembly, we separate the parts which will be refurbished from the ones which will be renewed.

This process is adapted for each part. For example, we use different cleaning methods depending on the part (Ultrasonic cleaning machine, pressurized water, sandblast, cleaning with specific detergents, and other special cleaning methods).

All parts are subjected to a rigorous exam and they are tested under strict criteria. So all of them are analyzed visually, mechanically and electronically (if necessary). One of the most used test is the hydraulic one.

This step is divided in many small phases. Each part is disassembled, cleaned, checked, and assembled again with new gaskets, seals, nuts, bolts, and other elements. Then they are submitted to various tests in order to guarantee that they accomplish our quality control.

Both new parts and refurbished parts are installed on the engine. During this, we are always checking that everything fits. In this step, RS Motor assembles each piece following the criteria of the engine manufacturer.

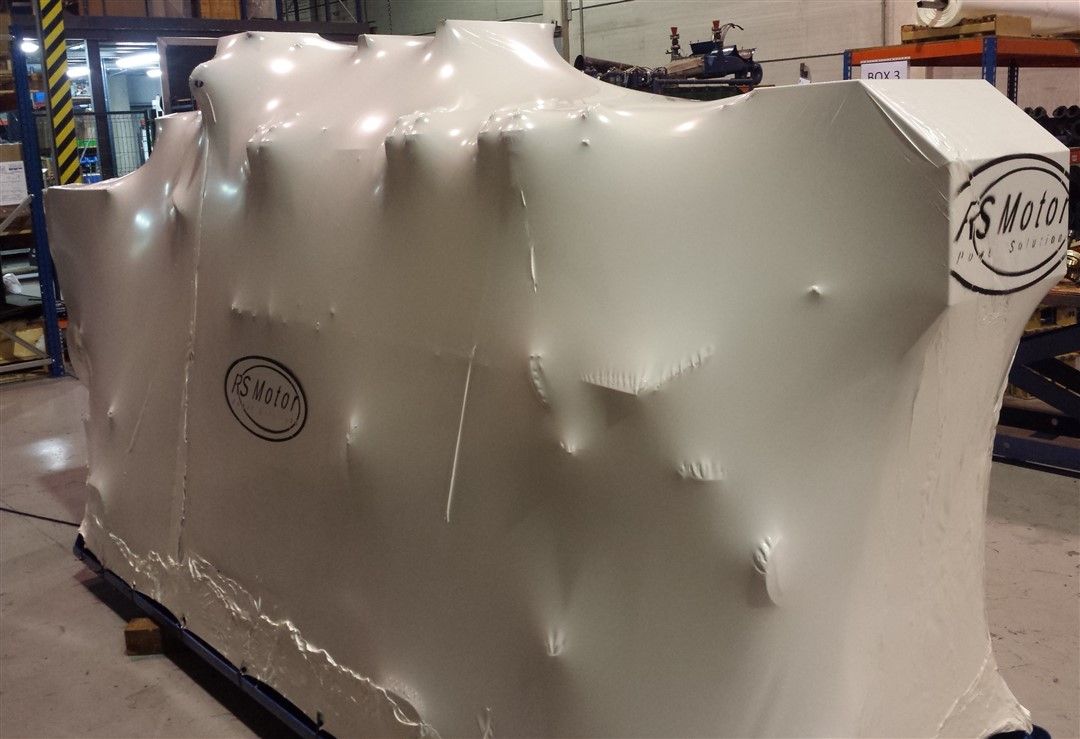

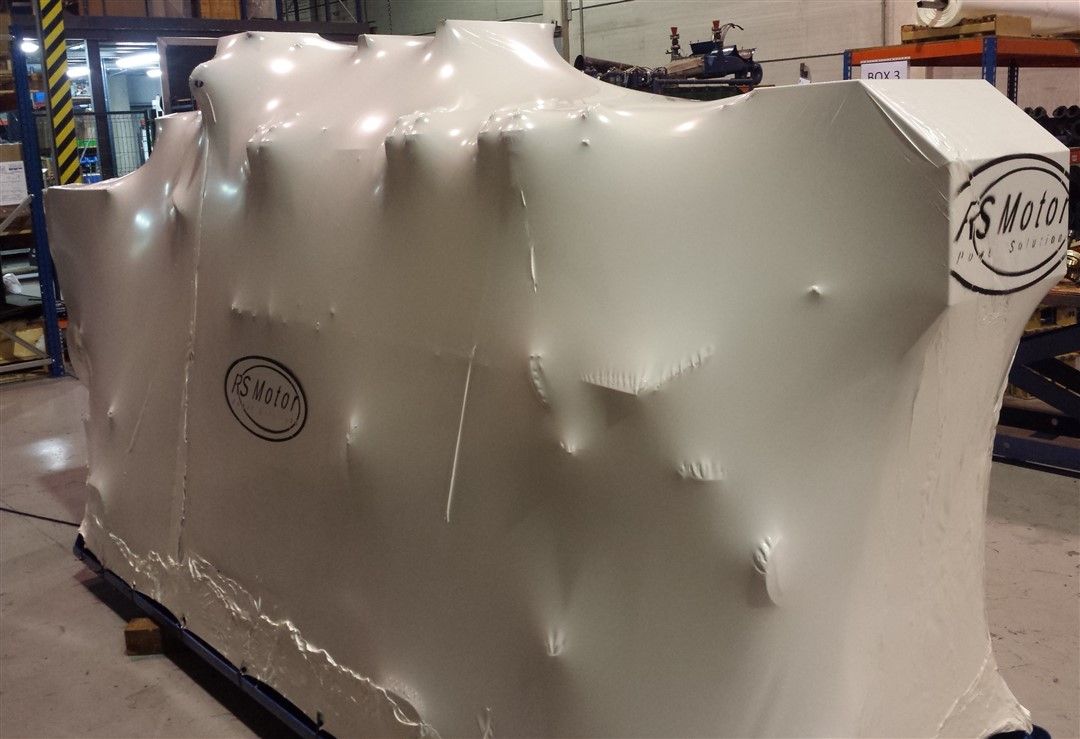

Once the engine is completely mounted, we perform a last strict essay and also we make a last visual checking before preparing everything for the shipment to the customer’s power plant.

During disassembly, we separate the parts which will be refurbished from the ones which will be renewed.

This process is adapted for each part. For example, we use different cleaning methods depending on the part (Ultrasonic cleaning machine, pressurized water, sandblast, cleaning with specific detergents, and other special cleaning methods).

All parts are subjected to a rigorous exam and they are tested under strict criteria. So all of them are analyzed visually, mechanically and electronically (if necessary). One of the most used test is the hydraulic one.

This step is divided in many small phases. Each part is disassembled, cleaned, checked, and assembled again with new gaskets, seals, nuts, bolts, and other elements. Then they are submitted to various tests in order to guarantee that they accomplish our quality control.

Both new parts and refurbished parts are installed on the engine. During this, we are always checking that everything fits. In this step, RS Motor assembles each piece following the criteria of the engine manufacturer.

Once the engine is completely mounted, we perform a last strict essay and also we make a last visual checking before preparing everything for the shipment to the customer’s power plant.